Localized necking or fracture may also occur in such cases. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. For aerospace and space applications, the values may be higher. Minimum bend radii requirements can vary depending on applications and material. Consequently, the depth of the embossed feature is restricted by the material’s thickness and ability to stretch in addition to the emboss geometry.It is recommended that the maximum depth of embossment be less than or equal to three times material thickness. Thereby the metal is subject to excessive thinning or fracturing. During this operation, stretching is the main deformation mode resulting in high tension. It is recommended that the diameter of the hole should be equal or more than the thickness of the sheet metal.Įmbosses are small, shallow formed projections on the surface of stamped parts. Small hole size in sheet metal requires smaller size punching tool which may leads to break during the operation. The diameter of the hole in sheet metal part should not be very small, small holes are created by piercing operation and for manufacture small holes, small sizes punches are required. It is recommended that the minimum distance between two extruded holes should be six times the thickness of sheet metal. If extruded holes are too close it can lead to metal deformation. It is recommended that the minimum distance between the extruded holes to part edge should be at least three times the thickness of sheet.Ĭertain distance should be maintained between two extruded holes in sheet metal designs.

If an extruded hole is too close to the part edge, it can lead to deformation or tearing of the metal. Minimum Distance from Extruded Hole to Part EdgeĮxtruding metal is one of the most extreme pressure applications in press working and generates lot of friction and heat. These guidelines may help companies to avoid rejections and rework due to engineering errors leading to higher cost of quality and delay in the delivery to customer.

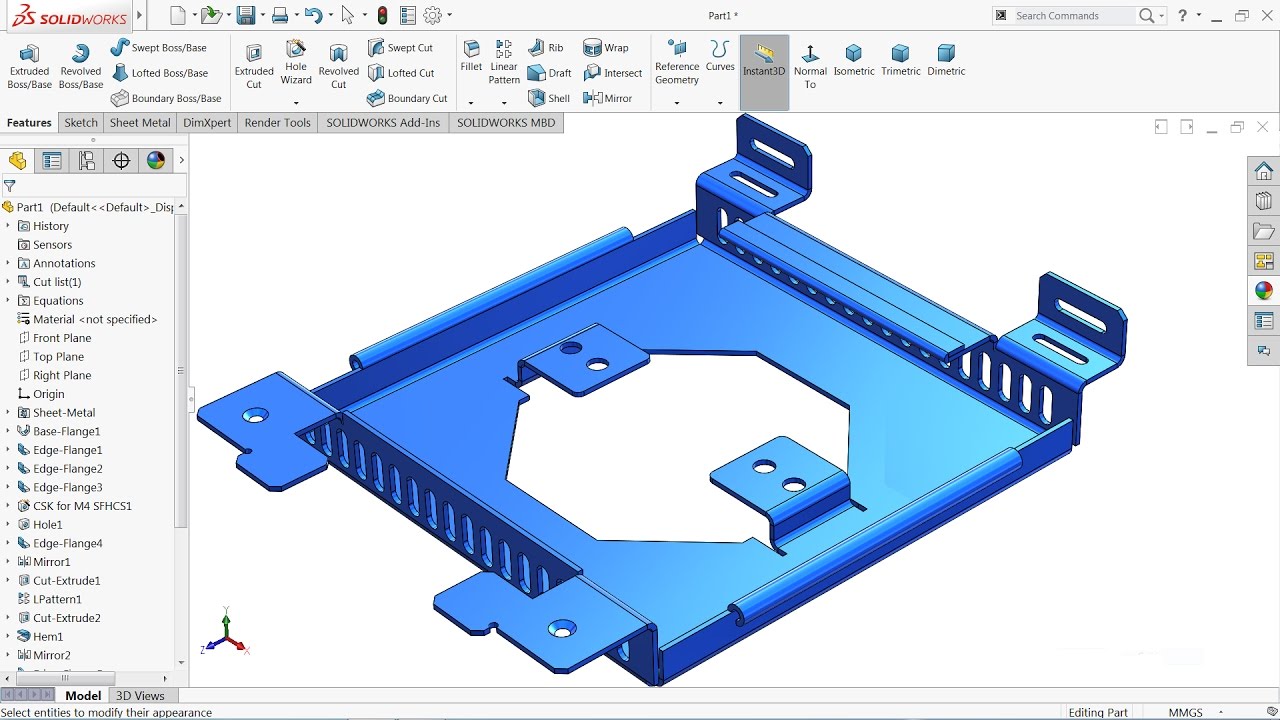

The section below contains examples of some design guidelines for sheet metal.

0 kommentar(er)

0 kommentar(er)